Slate gives the owner and roofer a much broader artistic palette than other roofing materials. As you will see in this section over the years many distinct styles of slate roofs have been developed.

Some of these styles roofs have come from necessity while others have come from aesthetics.

Triple M Contracting specializes in these attractive and historic methods of slate installation.

Standard Pattern Style

Common in USA . All slates in field of roof are same length and width.

Each slate is the same length and width. Each slate is fastened to the roof with two nails along a chalk line that marks the top edge of the slate. Each slate overlaps two courses below it. This overlap is called the “head lap” and is usually three inches. The head lap is one element of a slate roof that is essential. Slate sizes, widths, lengths, colors, shapes, and thickness can all vary, but the head lap is a constant that must be maintained.

A minimum three-inch head lap is standard, but greater head lap is acceptable anytime and is necessary when the roof slope drops toward 4:12 (which is minimum slope for slate roofs). Insufficient head lap can lead to roof leakage (although a two-inch head lap is common on older roofs with adequate slope ( 12:12 or greater).

Random Width Style

Slates are same length, but vary in width.

Each slate is the same length and width. Each slate is fastened to the roof with two nails along a chalk line that marks the top edge of the slate. Each slate overlaps two courses below it. This overlap is called the “head lap” and is usually three inches. The head lap is one element of a slate roof that is essential. Slate sizes, widths, lengths, colors, shapes, and thickness can all vary, but the head lap is a constant that must be maintained.

A minimum three-inch head lap is standard, but greater head lap is acceptable anytime and is necessary when the roof slope drops toward 4:12 (which is minimum slope for slate roofs). Insufficient head lap can lead to roof leakage (although a two-inch head lap is common on older roofs with adequate slope ( 12:12 or greater).

Staggered Butt Style

There are two easy ways to create staggered butt slate roofs. The first is to use slates all of one length, say 20″. The roof is chalked for 20″ slates with added head lap (4″ instead of 3″), or chalk lines every 8 inches. Slates of various widths should be used for aesthetic purposes, and various color shades will add even more to the beauty of the finished job. Every other slate is nailed above the chalk line about an inch or so during the installation. This reduces the head lap of the raised slates to 3″, which is acceptable. On steep slopes (greater than 12:12) even less head lap may be acceptable in some cases, allowing for a greater staggering effect.

If more pronounced staggering of the slates is desired, then chalk the slates for a five-inch head lap and nail every other slate two inches above the chalk line. The result is a beautiful roof. It requires a greater quantity of slates due to the extra head lap, but the artistic effect is worth it. Another method of installing a staggered butt slate roof is to use slates of different lengths.

For example, random width and preferably multi-colored slates that are 16″, 18″ and 20″ long can be nailed so that the top edges of all of the slates line up with the chalk lines. The roof is chalked for the 16″ slates with a 3″ head lap (a line every 6.5″). The effect is that the bottoms of the 18″ and 20″ slates hang down two inches and four inches more than the 16″ slates. Not only does this create a dramatic staggering effect on the roof, but it also allows for a “ragged” or “battered” butt style to also be utilized, if desired.

Slates may vary in length, or be laid on the roof to appear varied in length. In either case, the bottom exposed edge is staggered. The degree of stagger can vary from roof to roof. The photo above shows a 1″ stagger on a roof that is about 80 years old.

This roof is made of random width, mixed color, new and salvaged slates in a staggered butt style. The slates include VT unfading purple, VT mottled green and purple, VT sea green (new and salvaged), VT unfading green, VA Buckingham (salvaged), and NY red (salvaged). Lengths range from 16″ to 20″ and widths range from 8″ to 14″.

This photo shows a staggered butt roof with 3 lengths (14″, 18″ and 20″) with 4 colors of new slate: VT sea green (3/8 of roof surface), VT unfading purple (1/4), VT black (1/4), and VT unfading green (1/8), using 6 widths (7″, 8″, 9″, 10″, 11″ and 12″).

This photo shows a staggered butt slate roof with all the slates rounded by hand prior to installation. Lengths are 18″, 20″ and 22″ with a mix of widths including 9″, 10″, 11″, 12″ and 14″. The slates are about 50% new and 50% salvaged. Colors include VT unfading purple (new), VT unfading green (new), VT sea green (new and salvaged). Half of the roof is a mix of salvaged VT sea green slates. The remainder are new slates.

Another staggered butt slate roof (left) using heavy new VT slates with multi-colors.

Ragged Butt Style

Ragged butt slate roofs require some, if not most, of the slates to be to be trimmed erratically along the bottom edge before nailing into place. The end result is clearly a work of art, not difficult to achieve, and a lot of fun. Again, this style of slating utilizes more slates and requires more installation time, but when you know the roof is going to be looked at for a century or two, a little extra installation time doesn’t really mean that much when you’re creating a work of art. One of the most important elements of staggered and battered butt slate roof installations is the planning. The installer needs to know ahead of time how many slates of each width, length, and color are going to be used. For example, if you use 95% 16″ slates and 5% 20″ slates, the end result won’t look very good, you need a greater mix of sizes. Decide ahead of time what sort of color and size blend might look good, then have the entire selection on the job site before you get started.

Same principle as staggered butt, but the exposed edge is cut into random shapes or angles. This roof above is made from a mix of recycled slates.

Textural Style

The textural effect is created by periodically inserting two slates on top of each other where one slate would normally be. The lower slate in the pair is dropped down a couple inches and the slate on top is raised up a little. This provides thickness texture to the roof as well as staggers the exposed butt creating a unique and tasteful architectural style.

This textured PA black slate roof was installed in a very unique style. Longer slates are used in diagonal rows with thicker slates used nearer the bottom of the roof.

The same roof also utilizes thicker slates at random to enhance the textured look.

Graduated Style

Graduated roofs are the most traditional style of slate installation. The history of the graduated roof has its roots in ancient Scotland, England, and Whales. In the old slate quarries, the splitting of roofing shingles from rock was an arduous and exacting art. Many slate veins contained very hard, rough textured rock strata that could not easily be split into uniform, thin sheets required for shingles. For the sake of efficiency, the stone was split into the largest slate shingles possible, creating a supply of course shingles that varied considerably in size — some larger, some smaller. In order to make good use of all of these slates the graduated style of roof was developed.

In this style, the largest stones, sometimes massive, are installed at the bottom of the roof. This allows the heavier weight of these large stones, perhaps 30″ long and an inch think, to be born by the wall of the building. It also relieves the roofer of having to carry the flat stones, which may weigh 200 pounds, to the very top of the roof. As the roofer progresses up the roof, smaller and smaller slates are used, with the smallest slates, perhaps only 12″ long fastened to the top. The result is a roof that “graduates” in size from large at the bottom to small at the top, yielding an architectural style that is utterly unique and quite pleasing to the eye. Traditional graduated roofs also utilize random width slates. There are still many of these roofs in good condition scattered throughout the United States and Europe, yet the art of installing graduated slate roofs is a disappearing one.

Triple M Contracting prides itself on performing the most competent and historically accurate graduated slate roof restorations possible.

Once completed, a new graduated slate roof can be expected to grace a building and charm a community for at least a century, and maybe two.

This 90 year old roof had five slate lengths which graduate in 2″ increments according to an apparently random scheme. The slates on this 90 year old roof are nearly uniform in thickness (1/4″)

Mixed Shape Style

Different Shaped slates are used to produce even more artistic possibilities for your roof.

A common form of a mixed shape slate roof. slates are scalloped by hand and used in bands across the roof.

A less common example of mixed shape slate roofing, but quite dramatic nonetheless.

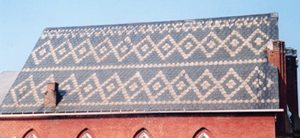

Patterns – Inscriptions

One of the unique characteristics of slate roofs is that slates can be used of different colors to create unique patterns, thereby creating landmark roofs.

The easiest procedure to use when installing an inscription or design on a slate roof is to draw a schematic of the roof beforehand. Make sure the schematic shows every slate in its proper proportion. The dimensions of the roof, as well as the size of the slates, must be known beforehand in order to do this job made easier by the use of a computer (although a computer was obviously not available in the 1800s when many dates were installed on slate roofs). Once the schematic has been created, the artist can play around with various designs until he or she has settled on one that looks good. Then it is only a matter of referring closely to the schematic during installation while using slates of contrasting colors in order to make the design appear on the roof. This doesn’t add a lot of time to the job, but it does create a lifetime landmark roof that can live long after the craftsmen who installed it have quietly passed away.